3-in-1 Automatic Water Bottling Machine (200-2000ml)

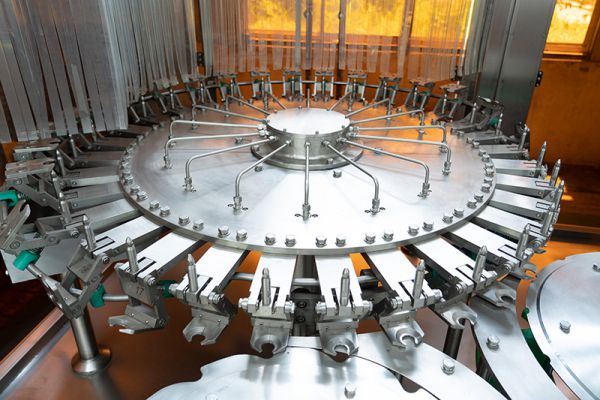

Monoblock Washing, Filling and Capping Machine for Drinking Water and Mineral Water

This 3-in-1 automatic water filling machine is a rotary monoblock system that fills purified water and mineral water in PET or glass bottles. It can implement washing, filling and capping of bottles with a capacity range of 200-2000ml. Equipped with PLC control and frequency converter, this automatic water bottling machine can guarantee highly automatic production and smooth operation, and the touch screen panel enables all settings to be easily accessible.

Basic Information

- Bottle type: PET bottles, glass bottles

- Cap type: plastic screw caps, sport closures, aluminum caps

- Bottle volume: 200-2000ml

- Washing method: adopting newly developed mechanical valve that precisely controls the rinsing fluid, without leakage of water

- Filling method: gravity filling system ensures stable filling process

- Capping method: magnetic clutch capping head is used for closing of plastic screw caps and sport closures, the torque is easily adjustable for reliable cap closing quality, while the aluminum cap closing system forms threads and seals aluminum caps onto bottles with exceptional ease and high tightness