Specifications

| Model | Production output | Filling heads | Power | Water consumption | Air consumption | Overall dimensions (L×W×H) | Weight |

QGF-60 | 60 b/h | 1 | 1.88 kW | 0.6 t/h | 0.18 m³/min | 2700×1200×1600mm | 400 kg |

QGF-120 | 120 b/h | 1 | 1.88 kW | 0.6 t/h | 0.18 m³/min | 3900×1200×1700mm | 600 kg |

QGF-300 | 300 b/h | 2 | 5 kW | 2 t/h | 0.4 m³/min | 5900×2300×1880mm | 2500 kg |

QGF-450 | 450 b/h | 3 | 7 kW | 2 t/h | 0.4 m³/min | 6000×2600×1880mm | 4000 kg |

QGF-600 | 600 b/h | 4 | 10 kW | 2 t/h | 0.4 m³/min | 6600×2800×1880mm | 4500 kg |

QGF-900 | 900 b/h | 6 | 20 kW | 2 t/h | 0.5 m³/min | 7400×3200×1880mm | 5000 kg |

Features

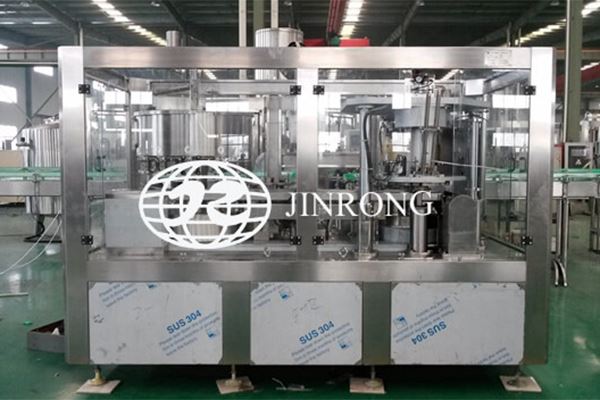

- This water bottling line integrates functions of sterilizing, washing, filling and capping, especially suitable for the filling of 3-gallon, 4-gallon and 5-gallon bottled water;

- The entire line is constructed with stainless steel, good corrosion resistance and easy to clean;

- Bottle washing with recirculating water, thus significantly saving water;

- Automatic bottle loading system helps improve working efficiency while reducing labor intensity;

- Omron or Siemens PLC control systems are used for reliable operation;

As an experienced manufacturer of liquid filling machines, Jinrong provides not only a wide variety of beverage filling equipment but also custom solutions adapted to your liquid or beverage packaging. With everything from liquid fillers to bottle labeling and packaging machines, we are able to provide complete liquid filling lines for almost any liquid packaging application, such as mineral water bottling line, soft drink canning line and fruit juice filling line. A complete beverage filling line consists of much more than just liquid filling machine or capping machine, Jinrong can help you fill the gap by offering technical support and after sales service. Please contact our experts to learn more about our liquid and beverage filling solutions.